Posted by Spycor Building on Oct 14th 2025

The silent killer of traditional stucco and manufactured stone veneer (MSV) systems isn't the sun, wind, or rain—it's trapped moisture. For decades, contractors have battled this issue, layering water-resistive barriers (WRBs), then adding furring strips or drainage planes, and finally securing metal lath. This multi-step process is time-consuming, labor-intensive, and inherently complex, increasing the risk of installation error and, ultimately, wall failure. When water inevitably penetrates the exterior cladding—which all claddings do—it gets trapped, creating the perfect environment for mold, mildew, and structural decay.

Today, the building industry demands a smarter solution. It needs a product that not only offers superior moisture protection but also drastically reduces installation time and labor costs on the job site. That solution is the DELTA®-DRY & LATH Rainscreen System, a truly revolutionary 2-in-1 product that is changing the way builders approach moisture management for absorptive claddings.

The Stucco and Stone Veneer Dilemma:

Why Traditional Methods Fail

Stucco and stone veneer are beloved for their aesthetic appeal and durability, yet they pose unique challenges regarding moisture management. Because these materials are absorptive, they soak up water during rain events. If that water has no path to drain and dry out, it remains pressed against the wall sheathing—a condition known as hydrostatic pressure. Over time, this constant dampness compromises the sheathing, the wall cavity, and even the structural integrity of the home.

Traditional building methods attempt to solve this with a sequence of separate components:

-

Water-Resistive Barrier (WRB): Applied directly to the sheathing.

-

Drainage Mat/Plane: A separate layer added on top of the WRB to create a gap.

-

Metal Lath: A third component fastened through both layers to provide the substrate for the stucco scratch coat.

This three-part system requires meticulous alignment, introduces multiple points of potential failure from excess fasteners, and doubles or triples the installation labor. Furthermore, traditional metal lath is corrosive, heavy, and can be difficult and dangerous to handle on the job site. This complexity is the root cause of many moisture-related warranty claims and costly remediation projects.

The Revolutionary 2-in-1 Solution:

DELTA®-DRY & LATH

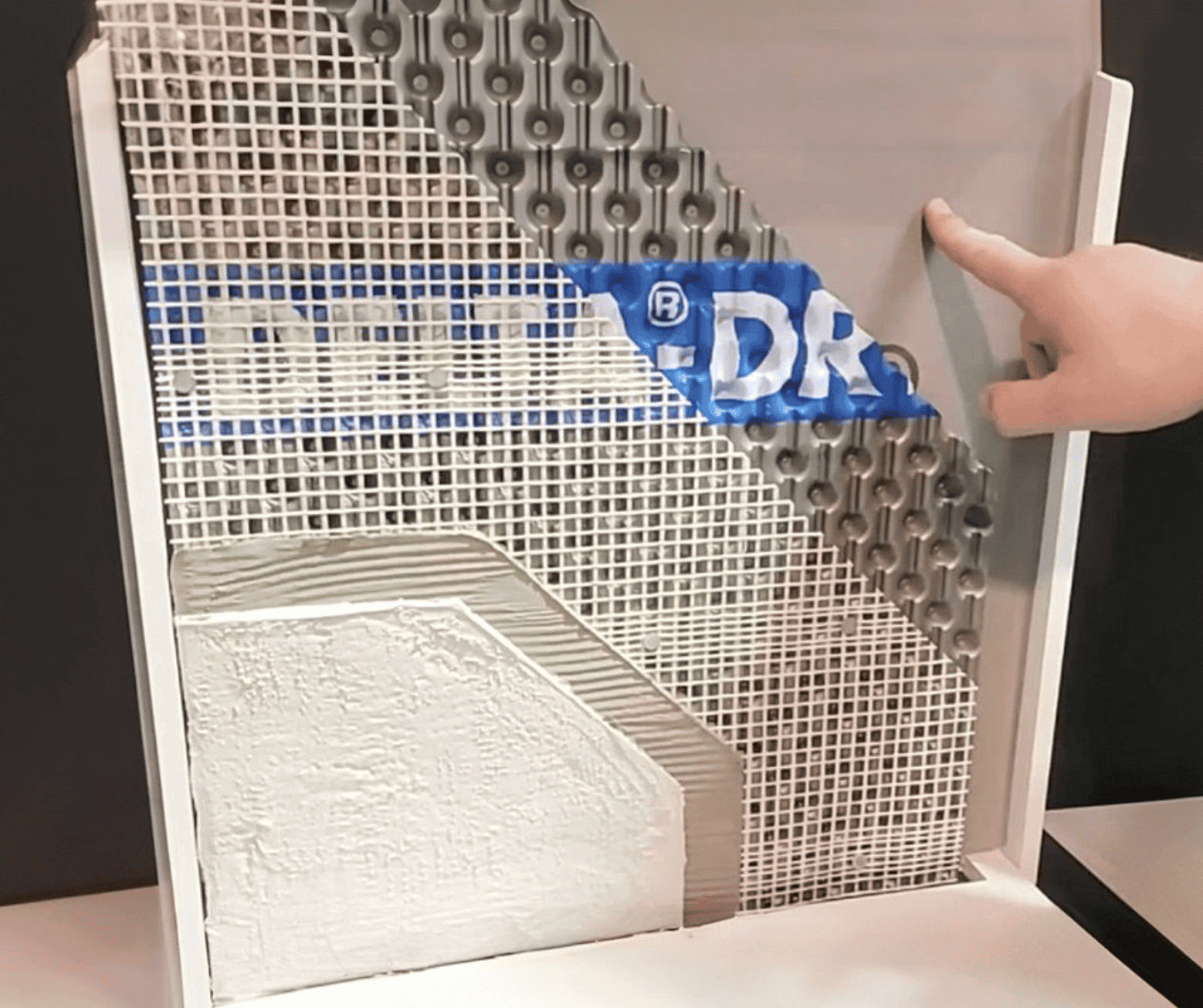

DELTA®-DRY & LATH eliminates the complex layering process by integrating two critical building components into a single, cohesive, 10.5 mm roll:

-

A High-Density Polyethylene (HDPE) Rainscreen Membrane: This functions as an impermeable, highly effective WRB that ensures water cannot penetrate the building envelope.

-

A Pre-Installed Alkali-Resistant Fiberglass Lath: This fiberglass mesh is securely bonded to the HDPE membrane, providing the ideal key for your scratch coat application, ready for either conventional stucco or manufactured stone veneer.

By combining the rainscreen (the moisture defense) and the lath (the stucco substrate) into one application, this product offers an unprecedented blend of performance, efficiency, and protection. It is a single product that delivers a complete, code-compliant, and fully ventilated stucco or stone veneer assembly.

The Contractor's Advantage: Cutting Time

and Costs with a Single Roll

For builders and contractors, time is the most valuable commodity. The largest, most immediate benefit of switching to the DELTA®-DRY & LATH system is the dramatic reduction in job site labor and material handling.

Massive Labor Savings

The traditional approach requires distinct crews or sequential tasks to install three separate layers. DELTA®-DRY & LATH collapses this entire sequence into one application step.

-

Eliminate a Step: By pre-installing the lath, you entirely bypass the time-consuming process of measuring, cutting, and securing a separate metal or synthetic lath over a drain screen.

-

Reduced Fastening: Fasteners are only applied once to secure the 2-in-1 roll. This not only speeds up the job but also minimizes penetrations through the crucial air and water barrier, reducing the risk of leaks.

-

Ease of Handling: The lightweight, rollable HDPE membrane is far easier and safer to transport, cut, and apply than heavy, sharp rolls of metal lath. The alkali-resistant fiberglass lath is also non-corrosive, eliminating the long-term risk of rust stains or degradation common with galvanized metal.

Switching to this integrated system can shave days off the installation schedule for large projects, translating directly into significant savings on labor costs—a critical factor in today's tight construction market. This efficiency is a powerful competitive advantage that allows contractors to complete projects faster and bid more competitively.

Engineered Protection: How the Air Gap

Works

The core technology behind the DELTA®-DRY & LATH system is the use of Air-gap Technology, which ensures superior long-term wall health. The product is not merely a water barrier; it is a meticulously engineered system designed to manage moisture kinetics.

Two-Sided Drainage and Ventilation

The High-Density Polyethylene (HDPE) membrane is formed with a unique dimple and groove design. When installed, these dimples create a continuous air space—the rainscreen gap—between the main wall structure and the back of the fiberglass lath. This gap serves three essential functions:

-

Immediate Drainage: Any water that penetrates the stucco or stone cladding can travel down the surface of the HDPE membrane and drain out at the base of the wall, safely away from the sheathing. The 10.5 mm profile ensures sufficient clearance for unimpeded vertical water flow.

-

Capillary Break: The air gap acts as a capillary break, preventing the wet stucco or stone from wicking moisture directly into the structure. The water is forced to stay on the exterior side of the membrane.

-

Ventilation and Drying: The air space allows for constant airflow (ventilation). This two-sided drying capability—drying both toward the exterior and into the air gap—is what sets the system apart. It ensures that any incidental moisture is quickly evaporated, drastically reducing the potential for mold, mildew, and rot to take hold.

This dual-purpose rainscreen action—draining bulk water and venting moisture vapor—provides long-term structural integrity and peace of mind for both the builder and the homeowner.

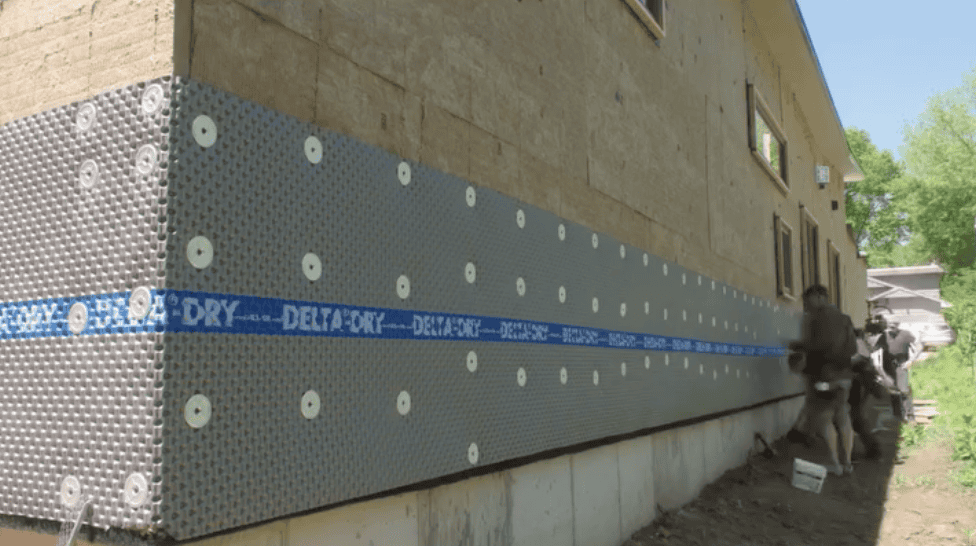

Installation Made Simple

The streamlined, single-step application of DELTA®-DRY & LATH is incredibly straightforward, maximizing the efficiency benefits on the job site. The system is designed to be user-friendly while maintaining the highest performance standards.

The rolls are designed for easy handling and efficient coverage, minimizing waste. After properly preparing the substrate and flashing the windows and doors, the membrane is applied horizontally or vertically (check local codes and manufacturer instructions). The installer secures the roll directly to the substrate using approved fasteners that penetrate the flat sections of the membrane. The fiberglass lath is then perfectly positioned to receive the stucco scratch coat.

To ensure flawless installation and to truly grasp the simplicity of the system, we encourage you to watch the official video:

How to Install DELTA®-DRY & LATH:

Code Compliance and Credibility: Peace of

Mind for Building Professionals

Using building materials that meet or exceed industry standards is paramount for avoiding costly re-work, passing inspections, and maintaining professional credibility. DELTA®-DRY & LATH provides this assurance.

The pre-installed, alkali-resistant glass lath complies with ICC-ES AC 275 (MVMA requirements), ensuring it is a suitable and approved substrate for manufactured stone veneer. Furthermore, the entire rainscreen system meets the rigorous standards of ASTM E2925-17 (Standard Specification for Manufactured Polymeric Drainage and Ventilation Materials Used to Provide a Rainscreen Function).

Choosing this product means selecting a system that has been tested, certified, and engineered to manage moisture effectively, providing architects, builders, and code officials with complete confidence in the final wall assembly. This compliance is a powerful selling point to quality-conscious homeowners and a safeguard for any contractor against future liability.

Conclusion: The Smart Choice for Modern

Cladding

In modern construction, complexity often equals risk and higher costs. The traditional method for installing stucco and stone veneer is an outdated, overly complicated process that leaves buildings vulnerable to moisture damage.

DELTA®-DRY & LATH is the intelligent alternative. It simplifies the wall assembly process by consolidating two essential steps into one, allowing contractors to reduce labor time and costs significantly. Simultaneously, it leverages advanced Air-gap Technology to provide a superior, ventilated drainage plane that actively protects the structure from water intrusion and vapor buildup.

By choosing DELTA®-DRY & LATH, you are not just buying a product; you are investing in a proven system for long-term durability, code compliance, and job site efficiency. It's the simplest path to a robust, moisture-free wall assembly. Stop complicating your projects and start building smarter.

Click Here to View Bulk Pricing and Secure DELTA®-DRY & LATH for Your Next Project!

Frequently Asked Questions (FAQ)

What is DELTA®-DRY & LATH?

DELTA®-DRY & LATH is a high-performance, 2-in-1 building wrap that combines a rainscreen drainage and ventilation membrane (made of High-Density Polyethylene, or HDPE) with a pre-installed, alkali-resistant fiberglass lath. It is specifically designed for use under absorptive claddings like stucco and manufactured stone veneer (MSV).

How does DELTA®-DRY & LATH prevent moisture damage?

It prevents moisture damage by creating a continuous air gap (rainscreen) between the wall sheathing and the back of the cladding. This air gap, formed by the unique dimple and groove design of the membrane, allows incidental water to drain safely down and out of the wall assembly, while also promoting ventilation for accelerated drying.

Is the lath fiberglass or metal?

The lath integrated into the product is a fiberglass mesh. This alkali-resistant fiberglass lath is non-corrosive, lightweight, and pre-applied to the HDPE membrane, eliminating the need to install traditional metal lath separately.

What are the main benefits for a contractor?

The primary benefits for contractors are reduced labor time and cost savings. Because it combines the water-resistive barrier, drainage plane, and lath into a single roll, it reduces the installation process from three steps to one, significantly cutting down man-hours and complexity on the job site.

What size is the drainage air gap?

The dimpled membrane of DELTA®-DRY & LATH creates an air gap of 10.5 mm (approximately 0.41 inches), providing sufficient space for effective bulk water drainage and continuous airflow for ventilation.

Is the product code compliant for stucco and stone?

Yes. The product meets or exceeds important industry standards, including compliance with ICC-ES AC 275 for the glass lath component and ASTM E2925-17 for the rainscreen drainage and ventilation function.

How does the 2-in-1 system compare to a separate WRB and lath?

A separate WRB and lath system requires three distinct, complex steps: installing the WRB, installing a separate drainage layer (if desired), and then installing a metal lath, each requiring individual fastening and flashing. The 2-in-1 DELTA®-DRY & LATH system is installed in a single step, minimizing labor, reducing fastener penetrations, and guaranteeing that the lath is perfectly positioned over the necessary drainage plane.