Posted by Spycor LLC on Oct 16th 2025

Clean air is critical for maintaining health, compliance, and productivity in commercial and industrial environments. Whether you're managing a hospital, factory, or office, questions about air quality solutions often lead to HEPA filters—renowned for their ability to capture fine particles like dust, allergens, and fumes. But what exactly makes HEPA filters effective, and how can they address your specific concerns? This guide answers the most common questions about HEPA filters, helping facility managers and business owners choose the right products for cleaner, safer air. Explore how these filters tackle real-world challenges and why they’re a smart investment for your space.

What Are HEPA Filters and Why Are They

Effective?

HEPA stands for High-Efficiency Particulate Air, a filtration standard that captures at least 99.97% of particles as small as 0.3 microns, including dust, pollen, mold spores, and some bacteria. These filters use a dense, pleated mat of glass or synthetic fibers to trap contaminants through interception, impaction, and diffusion. Air passes through the filter, leaving pollutants behind while allowing clean air to circulate.

In commercial and industrial settings, HEPA filters integrate into HVAC systems, air purifiers, or standalone units. For example, in a manufacturing plant, they remove welding fumes, while in healthcare facilities, they reduce airborne pathogens. Their high efficiency makes them ideal for environments requiring stringent air quality, meeting standards like ASHRAE 52.2 and OSHA regulations.

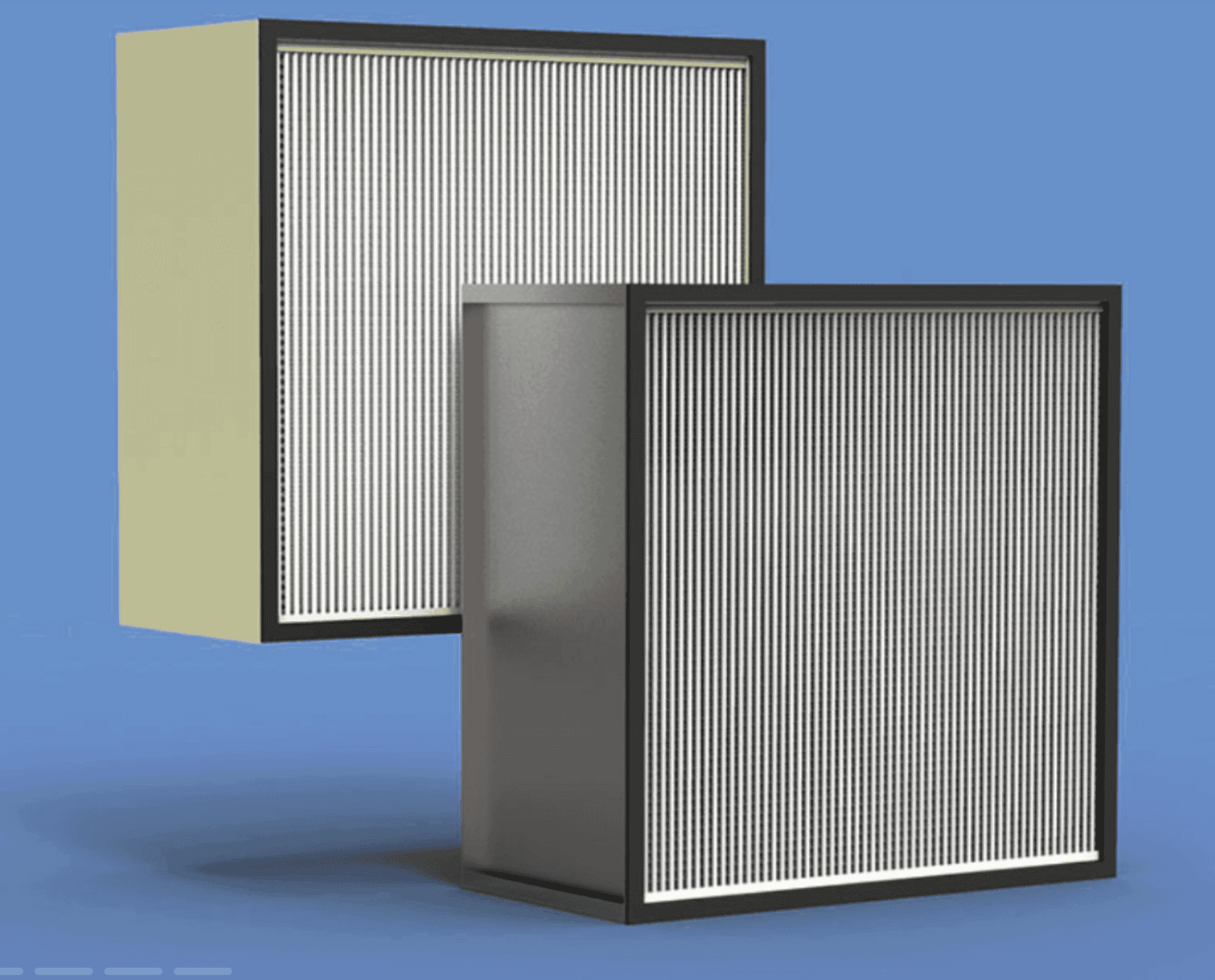

Key components include:

- Pleated Design: Maximizes surface area for better particle capture.

- Frame Options: Wood for cost-effective use or metal for durability in harsh conditions.

- Efficiency Variants: 99.97% for general use or 99.99% (ULPA-grade) for ultra-clean settings.

What air quality problems can HEPA filters solve?

Poor indoor air quality causes health issues, reduces productivity, and risks non-compliance with regulations. Common concerns include allergens, industrial fumes, and microbial growth. HEPA filters tackle these effectively:

- Allergens: Capture pollen, dust mites, and pet dander, reducing allergy symptoms in offices or schools.

- Fumes and Odors: Trap chemical vapors and smoke from manufacturing processes, improving worker safety.

- Mold and Bacteria: Prevent spores and microbes from spreading in humid environments like warehouses or labs.

For instance, a factory with metalworking operations saw a 90% reduction in airborne particulates after installing HEPA filters, per EPA case studies. This not only improved employee health but also extended equipment lifespan by reducing dust buildup.

Why should I invest in HEPA filters for my facility?

HEPA filters offer measurable advantages beyond basic air cleaning:

- Health Protection: By removing 99.97% of harmful particles, they lower risks of respiratory issues and infections, critical in high-traffic areas.

- Energy Savings: Optimized airflow reduces HVAC strain, cutting energy costs by 10-15% in some cases, according to DOE studies.

- Compliance: Meet stringent standards for cleanrooms, healthcare, or food processing facilities.

- Longevity: Durable designs last 6-12 months, minimizing replacement frequency.

In commercial offices, cleaner air correlates with 5-10% higher employee productivity, making HEPA filters a cost-effective choice.

How do I choose the right HEPA filter for my space?

HEPA filters come in various types to match specific applications:

- Standard HEPA (99.97% Efficiency): Great for offices, schools, or retail spaces handling common pollutants.

- ULPA-Grade HEPA (99.99% Efficiency): Suited for cleanrooms, labs, or hospitals requiring ultra-low particle levels.

- Wood Frame HEPA Filters: Lightweight and budget-friendly, ideal for low-humidity environments.

- Metal Frame HEPA Filters: Corrosion-resistant, perfect for industrial sites or coastal areas.

Consider your system’s airflow (CFM) and filter size (e.g., 24x24x12 inches for standard HVAC units). For high-dust environments, pair with pre-filters to extend HEPA life.

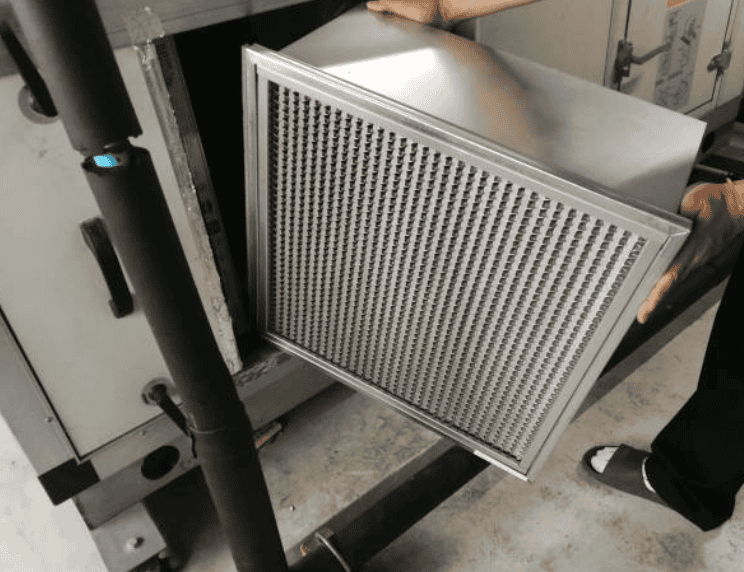

What’s the best way to install HEPA filters in my facility?

Proper integration ensures maximum performance. Follow these steps:

- Assess Air Quality: Use sensors to identify dominant pollutants.

- Match Filter Specs: Select size and efficiency compatible with your HVAC or purifier.

- Install Correctly: Seal edges to prevent air bypass, using gaskets or tape.

- Monitor Regularly: Check pressure drop to schedule replacements.

In industrial settings, combining HEPA with MERV 8-13 pre-filters extends lifespan by capturing larger particles first. For cleanrooms, ensure compliance with ISO 14644 standards.

Common pitfalls to avoid: Incorrect sizing or poor sealing, which reduces efficiency.

Are HEPA filters better than other air filters?

HEPA filters outperform standard filters in precision and efficiency:

HEPA filters are the go-to for environments needing high particle removal, offering superior value where air quality is critical.

What maintenance do HEPA filters require?

To keep filters performing:

- Replace Regularly: Every 6-12 months, or sooner in high-dust areas.

- Avoid Cleaning: HEPA filters aren’t washable; replace to maintain efficiency.

- Inspect Monthly: Check for clogs or damage, especially in industrial settings.

- Use Monitoring Tools: Manometers or differential pressure gauges signal when replacement is needed.

In factories, monthly checks prevent performance drops due to heavy particulate loads.

Choosing HEPA filters means prioritizing clean, safe air for your facility. With the right type and maintenance, you can address air quality concerns while boosting efficiency.

Click Here to explore the best HEPA filter options at Spycor.com and start improving your indoor environment today.

FAQ: Your Top HEPA Filter Questions

Answered

What particles do HEPA filters capture?

HEPA filters trap 99.97% of particles like dust, pollen, mold spores, and some bacteria as small as 0.3 microns.

Are HEPA filters suitable for industrial environments?

Yes, metal-frame HEPA filters excel in factories, handling fumes, dust, and chemicals effectively.

How often should I replace HEPA filters in a commercial setting?

Replace every 6-12 months, depending on usage and dust levels, to maintain optimal performance.

Can HEPA filters reduce energy costs?

By optimizing airflow, HEPA filters can cut HVAC energy use by 10-15%, per DOE studies.

Do HEPA filters help with regulatory compliance?

They meet ASHRAE and OSHA standards, ensuring compliance in healthcare, food processing, and cleanrooms.

Where can I buy high-quality HEPA filters?

Reliable suppliers like Spycor offer Glasfloss and Koch Filter HEPA products for commercial and industrial use.