Posted by Spycor Building on Nov 20th 2025

In regions where building projects face the brutal realities of winter, one question dominates the minds of architects, builders, and developers: Can our water-resistive barrier (WRB) withstand wind-driven snow and extreme cold before the final exterior cladding is installed?

The unequivocal answer, when using DELTA®-VENT SA from Dörken Systems, is yes. This premium, self-adhered membrane is specifically engineered to serve as a robust, temporary weather-resistant layer, providing superior sheathing protection and maintaining the integrity of the building enclosure through the harshest winter construction conditions. Far from being a simple house wrap, DELTA®-VENT SA is a high-performance air barrier and water-resistive barrier (WRB) designed for the severe demands of cold climates.

The Critical Challenge: Why Wind-Driven

Snow Demands a Superior WRB

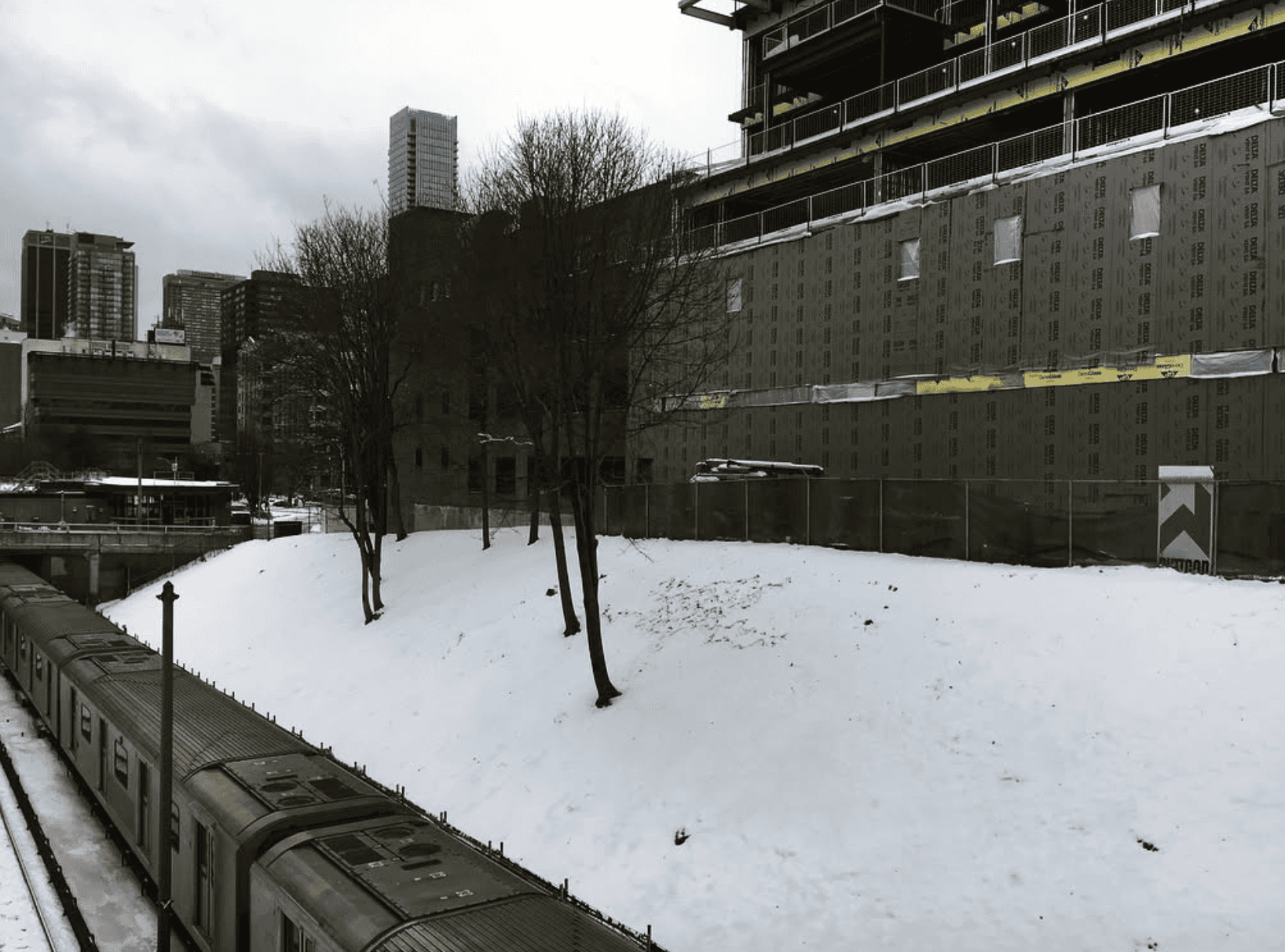

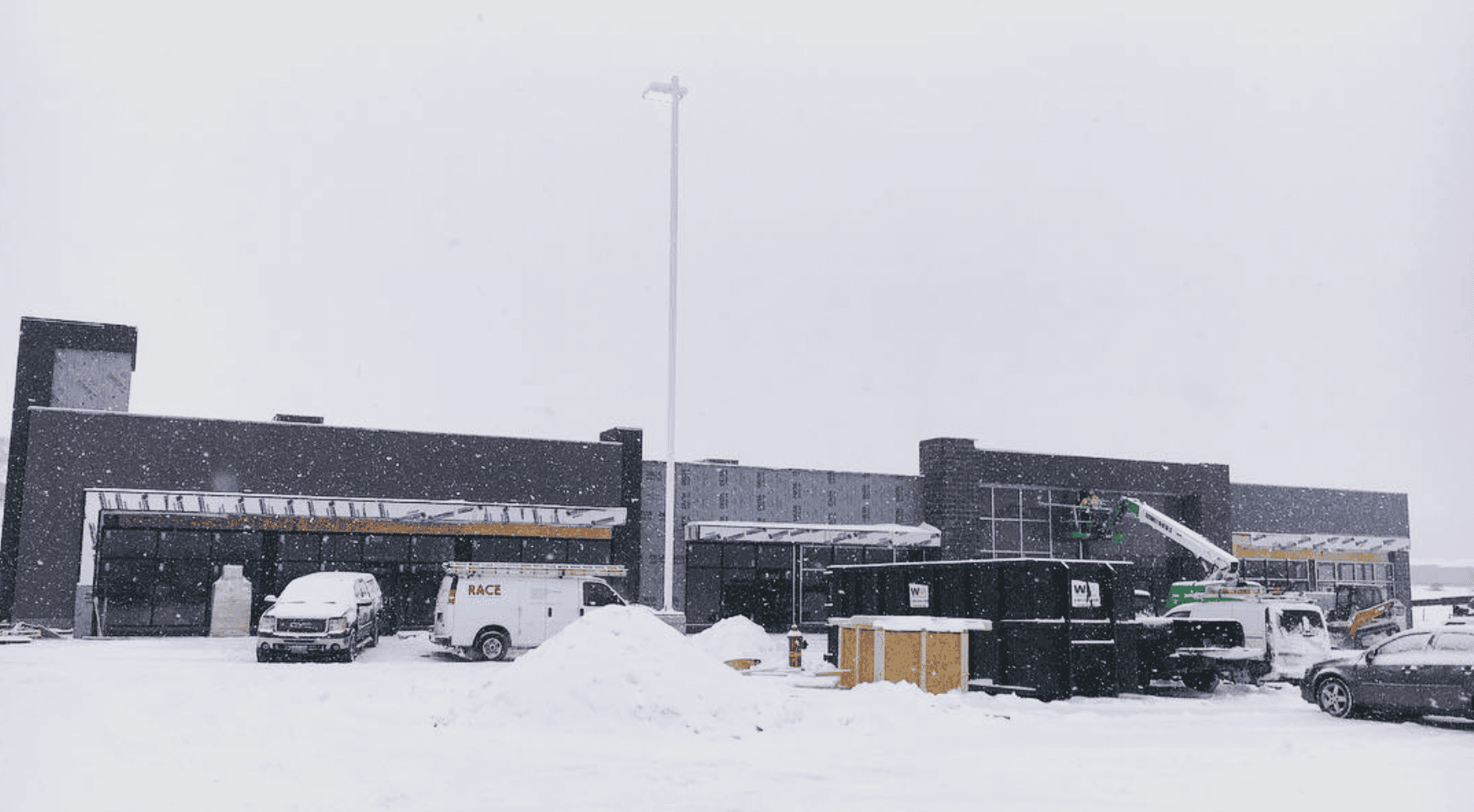

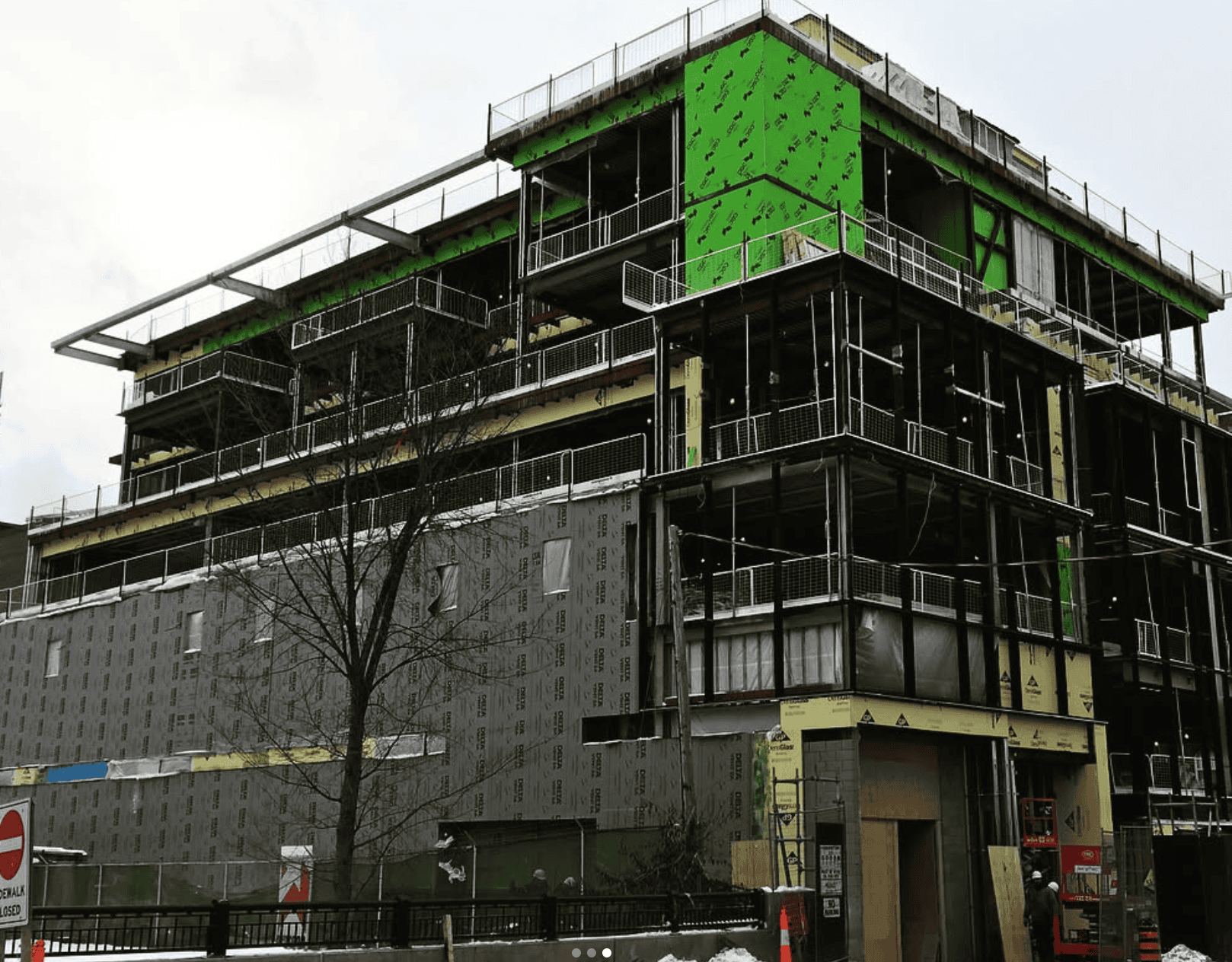

The construction timeline rarely pauses for weather, yet winter construction introduces profound risks to the building envelope. Builders often rely on the WRB to protect the sheathing (plywood, OSB, or exterior gypsum) for extended periods while waiting for materials or favorable conditions to install the final façade.

In cold climates, the primary threat isn't just liquid rain; it's the insidious nature of wind-driven snow. Unlike gentle snowfall, wind-driven snow is pulverized into fine particles that, under high wind pressure, can be forced through tiny gaps, seams, and even the smallest pinholes in a conventional, mechanically fastened WRB.

Once behind the WRB, this moisture melts, saturates the sheathing, and initiates a dangerous cycle:

- Rot and Mold: Prolonged saturation creates the perfect environment for biological growth.

- Reduced R-Value: Wet sheathing and insulation lose their thermal effectiveness, compromising the building's energy efficiency.

- Freeze-Thaw Damage: If the moisture freezes, it expands, causing irreversible deterioration of the sheathing material, potentially leading to structural issues.

To combat this, a water-resistive barrier for cold climates must provide complete, continuous protection—a requirement that DELTA®-VENT SA fulfills through its unique, self-adhering technology.

DELTA®-VENT SA: A Fully Adhered

Fortress Against Water Infiltration

The difference between surviving the winter and failing to maintain integrity lies in the method of application. Traditional WRBs are mechanically fastened with staples or cap nails, creating thousands of potential pathways for wind-driven snow and water ingress. DELTA®-VENT SA eliminates these vulnerabilities entirely.

1. Watertight, Self-Adhering Performance

The core feature that allows DELTA®-VENT SA to withstand severe weather is its aggressively self-adhered back layer. Once rolled onto the substrate (OSB, plywood, concrete, etc.), it forms a complete, tenacious bond across 100% of the surface area.

- No Fasteners, No Leaks: Since the membrane is fully adhered, there is zero reliance on staples or nails for general installation, meaning zero holes for water to exploit.

- Lateral Water Movement Eliminated: The full adhesion prevents any water that might breach the cladding later on (e.g., around windows) from traveling sideways behind the WRB, containing and directing the moisture downward. This is crucial for sheathing protection in high-exposure areas.

- Sealed Laps: The membrane features a self-adhesive edge lap with a release liner, creating a secure glue-to-glue sealed bond where the rolls overlap. This eliminates the chance of peeling and guarantees a truly watertight seam—the weakest point in any building envelope assembly.

2. High Durability and Jobsite Rigor

Winter construction sites are inherently harsh environments. DELTA®-VENT SA is built with a tough, 3-layer composition of spun-bonded polypropylene surrounding a watertight polymeric sheet. This composition provides high tensile strength and tear resistance, ensuring the membrane can endure the inevitable bumps, scuffs, and high winds typical of a cold-weather jobsite. Its resistance to the toughest wind and weather ensures it remains intact and fully functional until the final cladding is installed.

Managing Moisture and Energy in Cold Climates

While keeping bulk water and snow out is the priority, a high-performance WRB for cold climates must also function effectively as an air barrier and manage internal moisture—and this is where DELTA®-VENT SA truly excels, dramatically exceeding the requirements of the Air Barrier Association of America (ABAA).

The Peril of Air Leakage in Winter

In cold climates, warm, moist indoor air naturally seeks to escape through cracks and gaps in the wall assembly (air leakage). When this air hits the cold sheathing layer, the moisture condenses—often turning into frost or water within the wall cavity. This condensation is arguably more damaging than external bulk water because it occurs deep within the wall and is persistent.

By being aggressively self-adhered and forming a continuous, virtually gap-free seal, DELTA®-VENT SA achieves exceptional air-tightness. This air barrier function prevents the escape of warm, moist interior air, eliminating the primary cause of concealed winter condensation and protecting the structural integrity of the wall assembly long-term.

The Role of Vapor Permeability

A truly intelligent building enclosure requires the ability to dry out. Even with the best exterior defense, moisture can enter the wall assembly (e.g., residual construction moisture, minor leaks, or internal diffusion). DELTA®-VENT SA is highly vapor permeable, meaning it allows water vapor (a gas) to escape or diffuse through the membrane to the exterior.

This crucial property ensures that if any moisture does accumulate within the wall assembly—from wet lumber, rain, or condensation—it can dry out efficiently, preventing saturation and mitigating the risks of mold, rot, and freeze-thaw damage within the protected sheathing layers.

Longevity and Installation in Cold

Weather

When a builder commits to using a premium self-adhered WRB like DELTA®-VENT SA, they are investing in time—the time the sheathing can remain protected between the WRB application and the final cladding installation.

Extended UV Exposure Rating

The time a WRB can be left exposed to sunlight (UV radiation) and the elements before cladding is critical. While specific exposure limits should always be confirmed via the latest technical documentation, DELTA®-VENT SA is designed to offer robust temporary protection, making it a reliable solution for projects that anticipate delays in exterior finishing. Its durability and tear resistance ensure the membrane maintains its integrity and function even after prolonged exposure to wind, rain, and snow.

Installation Suitability

While the actual installation requires adherence to specific guidelines (like substrate preparation and temperature limitations for priming/adhesion), the nature of the self-adhered application means that once installed correctly, the performance of the air and water barrier is locked in. Working with high-quality primers where needed, installers can achieve the necessary bond strength to ensure the membrane provides continuous protection even as temperatures drop. The matte gray finish also aids in installation by reducing glare on bright, snowy days.

The Verdict on Sheathing Protection

For building projects in winter areas or cold climates, choosing a reliable water-resistive barrier that can act as a long-term sacrificial layer against the elements is non-negotiable. DELTA®-VENT SA provides this confidence.

Its fully adhered application eliminates the thousands of fastener holes found in conventional wraps, creating a seamless, airtight, and watertight layer that actively repels wind-driven snow, bulk water, and prevents damaging air leakage. By pairing this superior exterior defense with high vapor permeability, DELTA®-VENT SA ensures the sheathing remains dry, energy performance is maximized, and the entire building enclosure is prepared for a successful, long-lasting final cladding installation.

Yes, DELTA®-VENT SA is Engineered to Defend Against Wind-Driven Snow During Winter Construction

Order Now to secure your project and protect your investment against the harshest elements this season. Don't compromise your building envelope with standard materials.

Invest in the tested, premium performance of DELTA®-VENT SA to protect the integrity of your walls—and Order Now from spycorbuilding.com to protect your structure against wind-driven snow and catastrophic moisture infiltration.

Frequently Asked Questions (FAQ) about

Cold Climate WRBs

What is the primary difference between DELTA®-VENT SA and traditional house wrap in winter?

The primary difference is the adhesion method. Traditional house wraps are mechanically fastened, creating thousands of potential leaks around staples or nails, allowing wind-driven snow and water to penetrate. DELTA®-VENT SA is self-adhered and seals completely across the substrate, eliminating these holes and preventing the lateral movement of water behind the membrane, offering a far superior level of sheathing protection.

Does DELTA®-VENT SA function as a vapor barrier or a vapor permeable membrane?

DELTA®-VENT SA is a vapor permeable membrane. It is completely watertight and airtight, but it allows water vapor (gaseous moisture) to diffuse through it. This is crucial in all climates, especially cold climates, as it allows the wall assembly to dry out, preventing moisture accumulation, mold, and rot.

How does the air barrier function protect the wall in cold weather?

In cold climates, an effective air barrier stops the flow of warm, moist indoor air from reaching the cold sheathing layer. If warm air meets a cold surface, it condenses into water. DELTA®-VENT SA’s tested air-tightness eliminates this air flow, preventing concealed condensation and protecting the sheathing and insulation from moisture damage.

Can DELTA®-VENT SA be installed when temperatures are low?

While DELTA®-VENT SA is designed for high performance in cold climates, self-adhering products have specific minimum temperature requirements for initial application and adhesion strength. Consult the latest Technical Guide from Dörken Systems and the product instructions before installation in freezing temperatures. Primer is often used to ensure a proper bond in colder conditions.

How long can DELTA®-VENT SA be left exposed before final cladding?

The specific UV exposure rating (the maximum allowable time the product can be left exposed to the elements before being covered by cladding) is specified in the current ICC Evaluation Service Report (ESR) or the manufacturer's technical guide. Always consult the latest technical documentation to confirm the maximum exposure period for the project's location.