Posted by Spycor Building on Nov 24th 2025

For many homeowners, finishing the basement is the final step in unlocking a home’s full potential. It’s the dream of a new family room, home gym, or spacious office. However, that dream often butts up against the harsh reality of the subterranean environment: damp concrete slabs.

If you are a homeowner dealing with the musty smell, cold surface, or (worst of all) the signs of flooring failure—warped planks, peeling vinyl, or efflorescence (white chalky salt deposits)—you know the frustration is real. This is where you encounter the critical choice that separates a successful, long-lasting basement renovation from a costly, mildew-ridden mistake: selecting the best basement subfloor moisture barrier.

The truth is, concrete is not waterproof. It is a porous material, much like a dense sponge, constantly pulling moisture from the earth below and releasing water vapor upwards. If this vapor is trapped beneath your beautiful new finished flooring, the result is inevitable: mold, mildew, structural damage, and the complete failure of your investment.

To permanently conquer this challenge and achieve a truly dry, healthy, and comfortable basement, you don’t just need a thin sheet of plastic. You need a high-performance subfloor membrane system engineered to actively manage moisture and ventilation. This guide explores the proven technology that industry professionals trust—the dimpled polyethylene underlayment—and explains why it is the definitive solution for your damp concrete slab.

Understanding the Enemy: Concrete

Moisture and the Need for a Subfloor

Membrane

Before we dive into the solution, it’s essential to understand the unique moisture dynamics of a concrete basement slab. Most moisture problems stem from three primary sources:

1. Capillary Action (Wicking)

Even if you don’t have standing water, the ground beneath your home is damp. Concrete’s porous structure allows groundwater to be pulled upwards through the slab via microscopic channels—a process known as capillary action. This persistent wicking action brings water vapor, and often alkaline salts, directly to the surface of your floor, even through thick slabs.

2. Condensation (Sweating Slab Syndrome)

Basement floors are naturally cooler than the air above them, especially during warmer months. When warm, moist air meets the cold concrete surface, the moisture condenses, leading to a thin film of water on the slab. This is known as "sweating slab syndrome" and provides the perfect environment for mold and mildew growth beneath any floor covering.

3. Residual Water and Hydrostatic Pressure

Every concrete slab contains residual water from the mixing process that must evaporate. If a moisture barrier is not installed on the underside of the slab (during construction), or if you attempt to use an impermeable top coating (like epoxy or sealant) without proper preparation, you risk trapping the moisture. This can create powerful hydrostatic pressure—the force of water vapor trying to escape—which can lift, buckle, or delaminate even the most durable finished floor or adhesive.

Why Traditional Vapor Retarders Fall

Short

A simple, flat plastic vapor barrier (retarder) laid directly on the slab is a common mistake. While this material slows the transmission of moisture, it inevitably traps any moisture that does get through or condense, pressing it directly against the underside of your subfloor or finished material. This creates a highly saturated, airless environment—a breeding ground for mold, mustiness, and adhesive breakdown. To effectively manage moisture, you must provide a layer of ventilation and separation.

The Dimpled Membrane Revolution: Creating an Active Air Gap

The gold standard for basement moisture control—and the key to eliminating floor failure—is the dimpled membrane subfloor membrane. Products like DELTA-FL and Platon, often made from high-density polyethylene (HDPE), are specifically designed to address all three sources of concrete moisture simultaneously.

1. The Capillary Break and Moisture Barrier

The core sheet of the dimpled membrane acts as an immediate, physical, and highly durable separation layer. As a non-porous HDPE sheet, it achieves an incredibly low perm rating, providing a superior moisture and vapor barrier that stops water from traveling directly from the slab into the flooring system above.

2. The Built-In Air Gap and Ventilation

The innovation lies in the dimples. These raised cups—roughly 8 mm (5/16 inch) high—face down toward the concrete slab, creating a continuous, shallow air channel between the concrete and the new subfloor. This permanent air gap serves several critical functions:

-

Vapor Management: It allows any water vapor naturally emitted by the concrete to freely circulate and dissipate, rather than becoming trapped. This ventilation relieves vapor pressure, eliminating the destructive force of hydrostatic pressure that causes flooring adhesives to fail.

-

Thermal Break: The layer of air creates a thermal separation between your finished floor and the cold concrete below. This insulation makes the floor feel significantly warmer underfoot and reduces the chance of condensation or "sweating slab syndrome" forming on the surface.

-

Drainage Plane: If minor water intrusion occurs (such as a slow leak or seepage through a crack), the dimples channel the water safely beneath the membrane to the perimeter, where it can be directed toward a sump pump or floor drain.

By managing the movement of both moisture and air, the dimpled subfloor membrane transforms your cold, damp concrete slab into a benign, comfortable sub-base, ready to receive virtually any type of finished flooring.

Choosing and Installing a High-Quality

Subfloor Membrane

When selecting a subfloor membrane for your basement renovation, quality and specific features matter, particularly when aiming for a successful, long-term installation.

Key Features to Look For:

-

Material and Durability: Opt for membranes made from pure High-Density Polyethylene (HDPE). This material is resistant to mold, mildew, and decay, ensuring the membrane will last the lifetime of the structure. High-quality systems offer impressive compressive strength, meaning they can easily handle the weight of furniture, appliances, and high foot traffic without collapsing the dimples.

-

Dimple Height (Air Gap): A standard dimple height of around 5/16 inch (8 mm) provides the optimal balance of drainage, ventilation, and minimal floor height elevation.

-

Installation Method: One of the greatest advantages of using a roll-based system, such as DELTA-FL or Platon, is the ease of installation. These rolls simply lay out over the prepared concrete, with the dimples facing down. They are designed to "float" over the slab, which means:

-

DIY-Friendly: No messy adhesives, extensive tools, or complex fasteners needed in the center of the floor.

-

Crack Bridging: The membrane can safely span minor cracks and irregularities in the concrete surface without compromising its function.

-

Seam Sealing: The only critical step is sealing the seams. Always use the manufacturer-recommended, pressure-sensitive moistureproof tape designed to create a continuous vapor seal between the rolled sheets. (e.g., DELTA-MOISTUREPROOF TAPE).

-

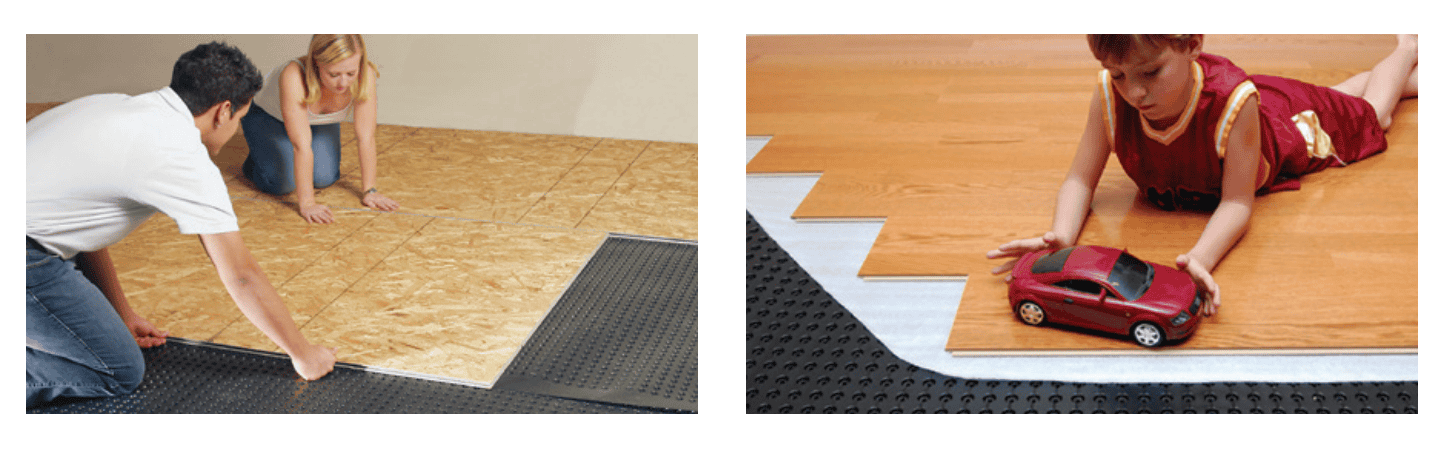

The Subfloor System Build-Up

Once the dimpled subfloor membrane is installed, you are no longer laying your finished floor directly over the concrete. You are installing a floating floor system:

-

Concrete Slab: The source of potential moisture.

-

Dimpled Subfloor Membrane: The waterproof, air-gapped protection layer.

-

Finished Subfloor (Optional): Many membranes can accept finished flooring directly, but for soft materials like carpet, or for added rigidity, you may float a layer of plywood or OSB on top of the dimples.

-

Finished Flooring: Laminate, engineered wood, vinyl, or carpet tiles.

This systematic approach is your best insurance policy against moisture-related failure and the key to a warm, dry, and healthy basement environment.

Securing Your Investment: Why the

Subfloor Membrane is Essential for All

Flooring

While some modern basement flooring options, like luxury vinyl plank (LVP) or ceramic tile, are inherently water-resistant, they are not immune to the dangers of moisture vapor transmission or the health risks associated with a cold, damp sub-base. The subfloor membrane protects more than just the floor material—it protects your home's air quality, structural integrity, and long-term value.

Protection Across All Floor Types:

-

Engineered Wood and Laminate: These materials are highly susceptible to moisture vapor, which causes warping, cupping, and swelling. The air gap provided by the dimpled membrane is non-negotiable insurance for these materials.

-

Carpet and Carpet Tiles: Moisture trapped beneath carpeting quickly leads to musty odors and mold growth. The membrane ensures the concrete can breathe, keeping the air space and the carpet backing dry and fresh.

-

Luxury Vinyl Plank (LVP) and Tile: Though water-resistant, LVP adhesive can fail due to efflorescence (alkaline salts pushed up by moisture) or hydrostatic pressure. The membrane protects the adhesive bond and provides a much-needed thermal break, making the floor far more comfortable.

Your Dry Basement Starts Now

Choosing the best basement subfloor moisture barrier is the single most important decision you will make in your basement finishing project. Do not settle for simple surface coatings or thin plastic sheeting. Demand the proven technology that provides an active moisture defense, thermal break, and pressure relief.

Invest in the longevity of your home and the health of your family with a superior dimpled subfloor membrane system. The peace of mind that comes from knowing your finished floor is protected against mold, decay, and failure is priceless.

Order Now at spycorbuilding.com to protect your investment with high-performance subfloor systems like DELTA-FL and Platon!

Frequently Asked Questions (FAQ) About

Subfloor Moisture Barriers

Why can’t I just paint a sealant on the concrete slab?

Concrete sealants (topical coatings) primarily address surface moisture, but they are often vapor retarders, not absolute barriers. They can trap moisture and salts within the slab, causing the coating to eventually bubble, crack, or delaminate due to vapor pressure. A dimpled subfloor membrane system, in contrast, actively manages and dissipates this pressure through its air gap.

Does a dimpled subfloor membrane provide insulation?

While it is not a dedicated insulation product like rigid foam, the air gap created by the dimples acts as a highly effective thermal break between the finished floor and the cold concrete slab. This trapped air layer reduces heat loss and condensation, making the floor significantly warmer and more comfortable than flooring laid directly on concrete.

Is this kind of subfloor membrane difficult for a DIY homeowner to install?

Not at all. High-quality dimpled membranes like DELTA-FL and Platon are favored by DIY homeowners due to their lightweight roll format. Installation primarily involves cutting the material to fit and properly sealing the seams with the specialized moistureproof tape. The system "floats" and does not require extensive mechanical fastening to the concrete.

What is the difference between a vapor barrier and a subfloor membrane?

A vapor barrier (or retarder) is typically a thin sheet of plastic designed only to slow vapor movement. A high-performance subfloor membrane (like a dimpled HDPE product) is a multi-functional system that serves as a capillary break, a waterproof barrier, and a vital air-gap management system, protecting the floor from both moisture intrusion and destructive vapor pressure.

Can I install tile directly over a dimpled membrane?

Generally, no. Tile requires a rigid, stable subfloor. You must install a rigid layer—usually two layers of plywood or OSB, or a cement backer board system—floating over the dimpled membrane before applying tile. Always follow the specific subfloor preparation guidelines for your finished flooring material.