Posted by Spycor LLC on Oct 1st 2025

For too long, small and mid-sized construction, remodeling, and restoration teams have operated under a frustrating dichotomy: either invest heavily in large, truck-mounted air purification systems designed for massive commercial projects, or risk the consequences of inadequate dust, mold, and particulate containment. That calculus ends now.

The days of relying on shop vacuums and simple fans to manage job site air quality are over. Regulatory pressure from OSHA, the rise of specialized high-value remediation services, and increasingly health-conscious clients demand professional-grade containment. This is not about installing another bulky piece of equipment; it is about adopting streamlined, affordable negative air machines—specifically engineered portable air scrubbers for small construction teams—that transition from a compliance cost into a competitive advantage.

This deep-dive guide is dedicated to the practical contractor. We’re not selling you on the necessity of air filtration—you already know the risks of asbestos, lead, silica dust, and mold spores. Instead, we provide the technical roadmap, cost-saving strategies, and exact CFM specifications needed to implement professional-grade HEPA air filtration without overspending or sacrificing job site mobility. Your focus is delivering quality on time and on budget; our focus is making sure the air quality doesn't compromise that promise.

The Core Problem: Why Small Teams

Can't Afford to Skip Air Quality Compliance

The term "affordable" must be understood in context. An inexpensive solution that fails compliance checks, causes cross-contamination, or forces a work stoppage is the most expensive mistake a small contractor can make. The goal is to maximize ROI on negative air machine investment through smart purchasing and consistent deployment.

1. The Real Cost of Construction Dust and Particulates

Visible dust is the least of your concerns. The true threat comes from invisible, sub-micron particulates that bypass standard vacuum and furnace filters:

- Crystalline Silica Dust: Generated from cutting concrete, stone, or brick. Highly regulated by OSHA due to its link to silicosis.

- Lead and Asbestos: Present in nearly every structure built before 1978. Abatement requires strict negative pressure containment.

- Mold Spores: Activated by water damage or high humidity. Spores spread rapidly without HEPA air filtration, expanding a $5,000 repair into a $25,000 remediation disaster.

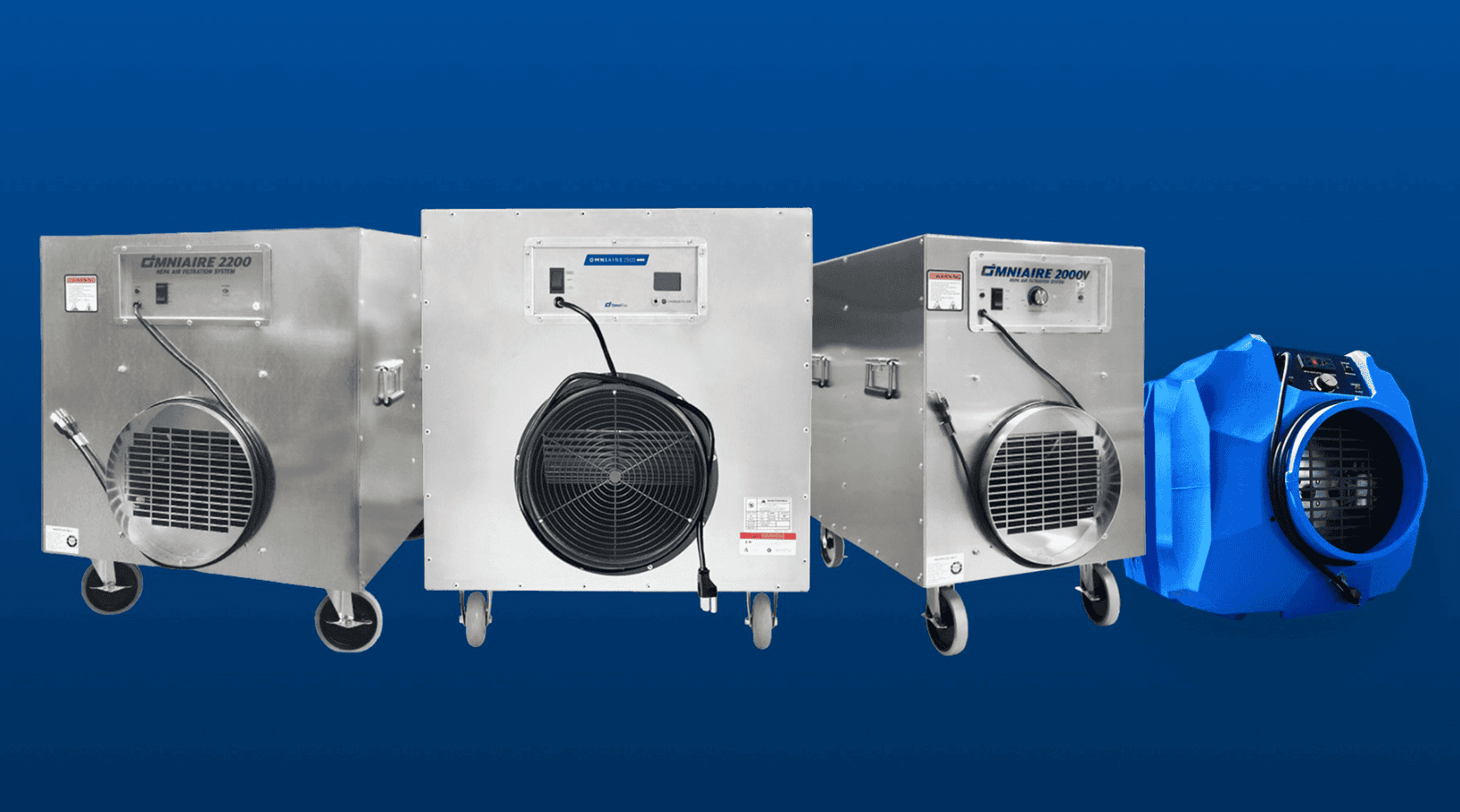

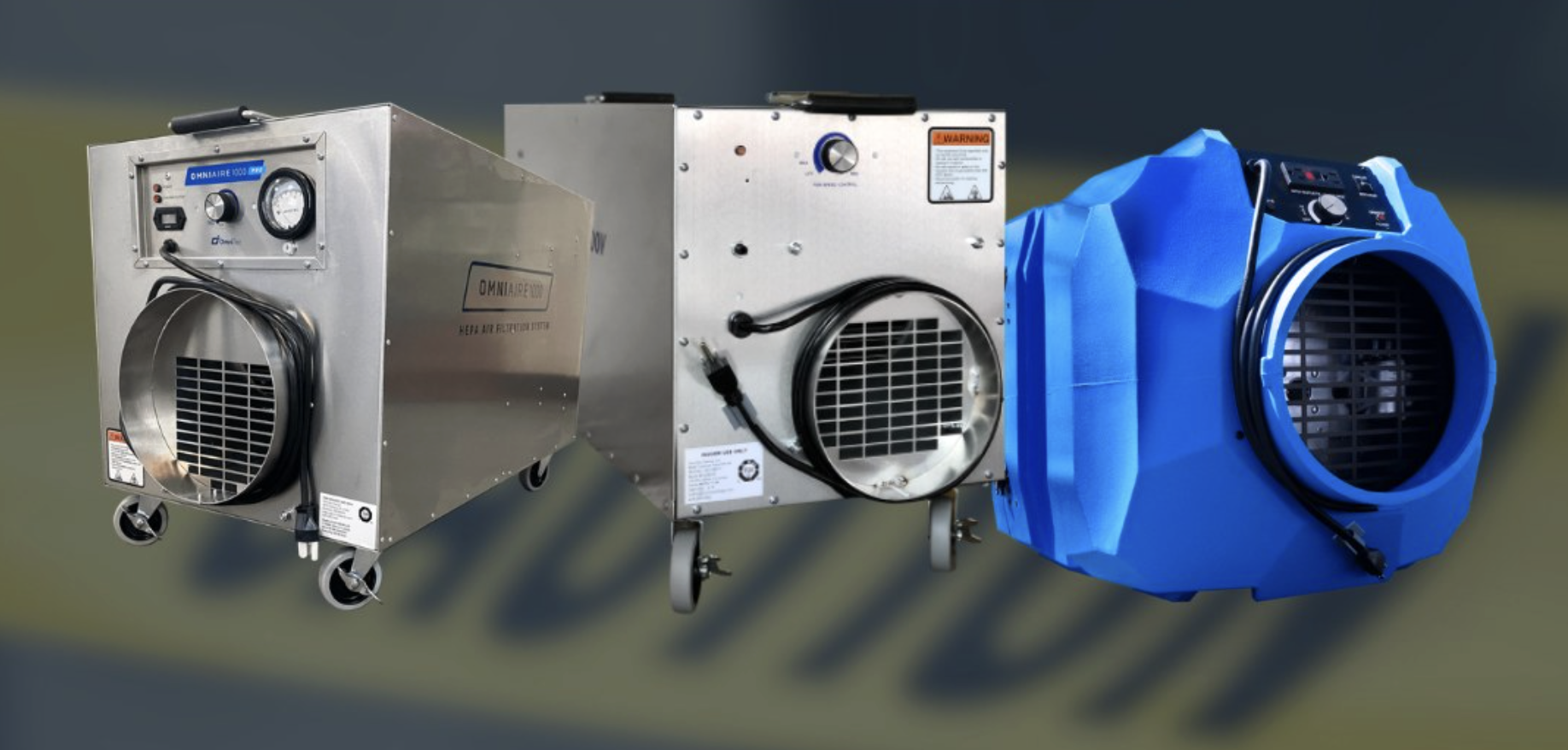

For a small team, a single OSHA violation can result in fines that bankrupt the business. A single contaminated job site can destroy your reputation. Portable negative air machines like the specialized NCF600 or the Predator 750 Portable Air Scrubber are not a luxury; they are a necessary insurance policy against financial ruin and liability.

2. The Shift to Portable, Low-Amperage Designs

Legacy negative air machines were often large, consuming high amperage and requiring dedicated circuits. Modern, construction portable machines are optimized for the reality of today’s job sites:

- Low Amperage Draw: Many high-efficiency units draw less than 2.0 amps, allowing multiple units (or daisy-chaining) to run safely on a single 15-amp residential circuit, a crucial factor for older homes and small commercial spaces.

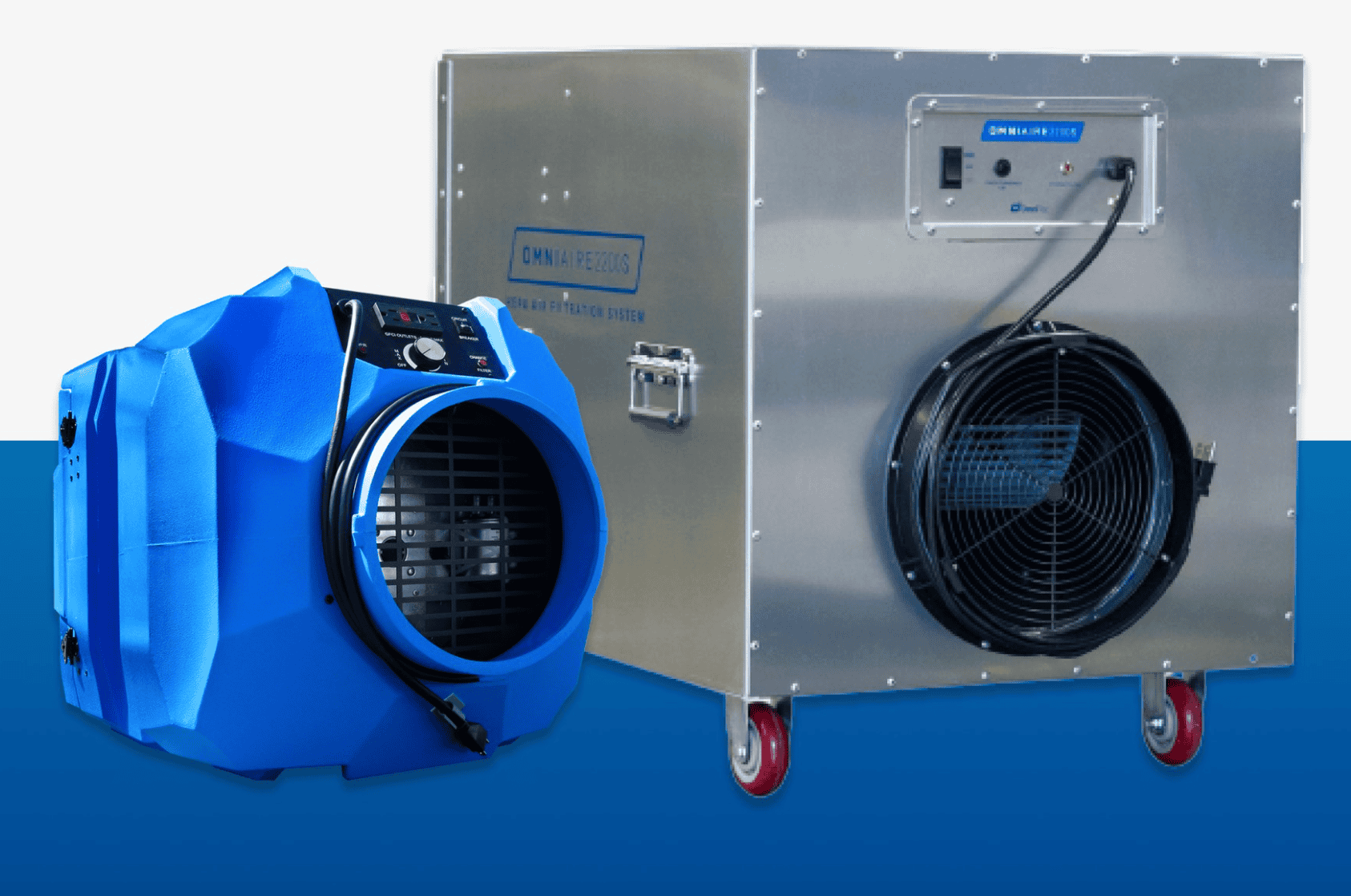

- Lightweight Durability: Units built with double-wall, roto-molded polyethylene cabinets (rather than heavy metal) are virtually indestructible, non-marking, and easy for one person to move up stairs or into crawlspaces. This is the definition of portable air scrubber for construction.

- Variable Speed Control: The ability to dial down the CFM means you can use the same machine for a tiny closet mold cleanup (requiring lower CFM) as you would for a medium-sized bathroom remodel, maximizing the unit’s utilization rate and saving money.

Decoding the Jargon: Negative Air Machine

vs. Air Scrubber

The terms Negative Air Machine and Air Scrubber are often used interchangeably, but understanding the subtle difference is critical for effective containment and compliance.

The True Difference: Function vs. Pressure

- Air Scrubber: A device that filters the air in a space, running the ambient air through pre-filters and a certified HEPA filter and re-releasing the clean air back into the same room. It scrubs the air to improve indoor air quality (IAQ) and reduce overall dust load.

- Negative Air Machine (NAM): An Air Scrubber with a specific purpose. When an air scrubber is vented via ducting to the outside of the containment zone (or into an uncontaminated area), it actively removes more air than it allows to enter. This creates negative pressure containment. The lower pressure ensures that air—and all dangerous particles—can only flow into the containment area, never out. The air is then passed through a HEPA filter before exhausting.

Why Small Construction Teams Need Both Functions:

- Containment: When dealing with hazardous materials (mold, lead, asbestos), you must use the machine as a Negative Air Machine to prevent contamination spread.

- General Dust Reduction: During standard demolition, drywall sanding, or construction phases where hazardous materials are not confirmed, the unit can be used as a simple HEPA Air Scrubber to dramatically reduce dust for a cleaner, healthier workspace, fewer worker respiratory issues, and less post-job cleanup.

The Small Team’s Sweet Spot: High-

Efficiency, Low-CFM Powerhouses

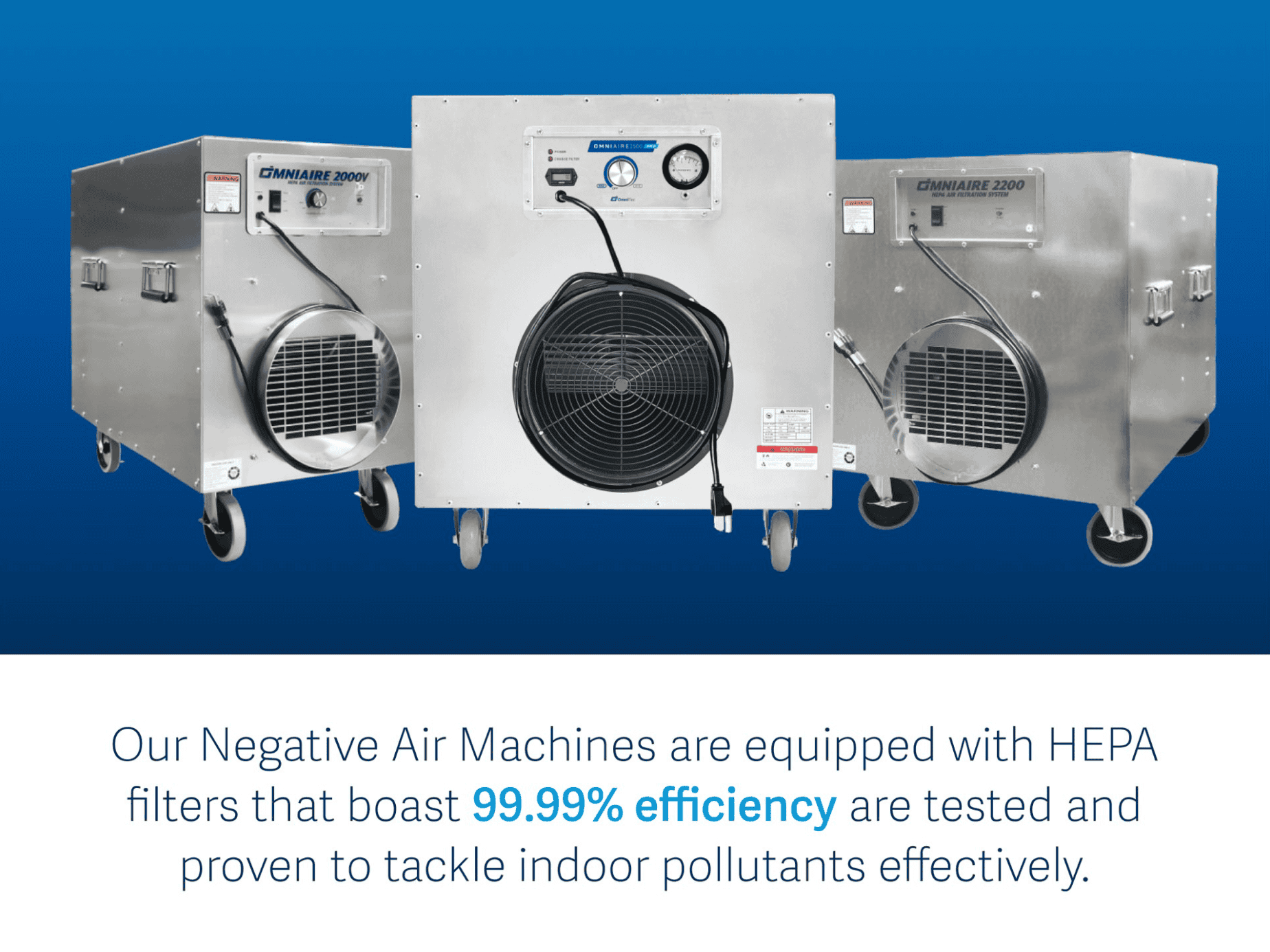

The products featured on the Spycor Construction Portable Machines page are not overkill—they are precision tools. They represent the sweet spot where power, mobility, and affordability intersect. They are designed for the contractor who needs maximum performance in a minimal footprint.

A Closer Look at the Ideal Affordable Negative Air Machine

When selecting a unit, small teams must prioritize three core features that directly impact long-term costs and job site efficiency:

1. True HEPA Filtration: Non-Negotiable Compliance

The heart of any negative air machine is the filter. You must look for True HEPA Filtration, which means the filter is individually tested and certified to capture 99.97% of airborne particles down to 0.3 microns. Anything less is a costly risk.

- Pre-Filters: To protect the expensive HEPA filter, the machine should use a series of lower-cost pre-filters (usually MERV 8 or MERV 11) that capture the large, visible construction dust. A smart machine design allows for quick, tool-free replacement of these pre-filters, dramatically extending the life of the primary HEPA filter. This is where the long-term affordability of the unit shines through.

- Differential Pressure Gauge/Indicator: Professional units are equipped with an indicator (either a simple gauge or a light) that alerts the operator when the filter is loaded and needs to be changed. This eliminates guesswork and ensures the machine maintains its effective CFM rating—a key compliance point.

2. Durability and Transport: The Roto-Molded Advantage

Small construction and restoration teams move equipment constantly. Durability is a factor of affordability. A machine that cracks or fails after a few months on a rugged job site has a hidden cost of replacement and downtime.

The best portable units feature:

- Roto-Molded Polyethylene Housings: This material resists dents, punctures, chemical exposure, and moisture damage. Unlike galvanized steel, polyethylene is lightweight and will not mark floors or containment walls during transport.

- Sealed Seams: For negative pressure to work, the housing must be airtight. Look for models with silicone-sealed seams to ensure all incoming air is forced through the HEPA filter and does not bypass the system (a critical failure point in cheaper machines).

- Stackable Design: The ability to stack units two or three high saves precious space in the work van and storage facility, improving logistics efficiency.

3. Low Amperage and Daisy-Chain Capability

The ultimate mark of a machine designed for small, flexible teams is its power efficiency and electrical connectivity.

Units like the PRED750 Predator Portable Air Scrubber are highly efficient, often drawing less than 2 amps at full speed. This means:

- Daisy-Chaining: You can safely plug one machine into another, allowing you to run multiple units off a single wall outlet or generator. Running two 750 CFM units together provides 1,500 CFM of compliant filtration capacity, enough for a 5,000-square-foot containment area (with 8-foot ceilings). This scalability is how small teams handle larger jobs without owning a massive inventory of equipment.

- Residential Circuit Safety: Avoiding tripped breakers and electrical overloads in residential settings is crucial. A low-amp draw machine is a professional courtesy to the client and a time-saver for your crew.

The Three Killer Applications for Portable

Negative Air Machines

A single, versatile portable negative air machine can generate high-margin revenue across multiple, specialized services. The ability to guarantee a safe, contained environment is the competitive edge small teams need to transition from general contracting to lucrative remediation and abatement.

A. Mold Remediation: The Revenue Generator

Mold remediation is the most common reason small teams purchase a dedicated negative air machine. Mold spores are microscopic (2–10 microns) and incredibly volatile. Any disruption—sanding, scraping, demolition—will aerosolize millions of spores, which can settle and start new growth in a clean area within hours.

The Negative Pressure Protocol:

- Seal the Zone: Create airtight containment using poly sheeting and zipper doors.

- Establish Negative Pressure: Place the HEPA air scrubber inside the containment area and duct the exhaust air to the outside of the building.

- The Containment Lock: The negative pressure ensures that if any breach occurs (e.g., a worker enters or exits), air is drawn into the contained area, not out. This prevents spore migration and ensures a clean final clearance test.

Key Insight: By purchasing a certified, reliable machine, you can confidently offer a Mold Remediation Guarantee, securing the business from less-equipped competitors.

B. Lead and Asbestos Abatement: The Compliance Essential

Any project disturbing materials containing lead (paint) or asbestos (pipe insulation, flooring, acoustic ceilings) requires mandatory containment under federal and state regulations. For small construction teams engaging in renovation, demo, or retrofitting, the negative air machine moves from a best practice to a legal necessity.

Compliance Must-Haves for Abatement:

- True HEPA 99.97% Efficiency: This standard is non-negotiable for capturing fine asbestos fibers and lead dust.

- Ducting and Airflow: Use sealed ducting to exhaust the air safely. In most cases, abatement rules require the exhaust to be placed outside the structure.

- Variable CFM Control: Lead and asbestos abatement often occurs in small, confined spaces. Variable speed machines allow the operator to adjust the flow to maintain optimal negative pressure without creating excessive vacuum that stresses the containment barrier.

C. ICRA and Sensitive Environment Construction

Small teams often take on renovation work in occupied buildings, schools, offices, or healthcare facilities (Infection Control Risk Assessment, or ICRA). These projects pay a premium because of the high compliance burden.

A portable air scrubber is the single most important piece of ICRA equipment. It prevents construction dust, fungi, and bacteria from entering sensitive patient or clean zones. The lightweight, non-marking, and quiet nature of modern units is essential in these environments.

Why Portability Wins ICRA Bids:

-

ICRA containment zones are often fluid and small. A compact construction portable machine can be easily moved, nested, or stacked to provide flexible air management in hallways, above ceilings, or within temporary enclosures, a capability that large, fixed units cannot match.

The Path to Profitable Containment

Small construction teams are the backbone of the building and restoration industry. You need equipment that is as agile, reliable, and cost-effective as you are. Investing in the right affordable negative air machines is the most direct path to securing complex, high-value abatement contracts and separating your business from competitors still relying on dusty, outdated methods.

By selecting low-amperage, high-efficiency, and durable HEPA air scrubbers—machines purpose-built for the rigors of frequent transport and varied job sizes—you ensure safety, guarantee compliance, and maximize your profitability on every containment project.

Your next high-value project demands the best. Don't let contaminated air be the reason you lose a bid or fail an inspection.

Click Here to explore the top rated Affordable Negative Air Machine and Portable Air Scrubber perfect for small construction teams and claim your competitive edge today!